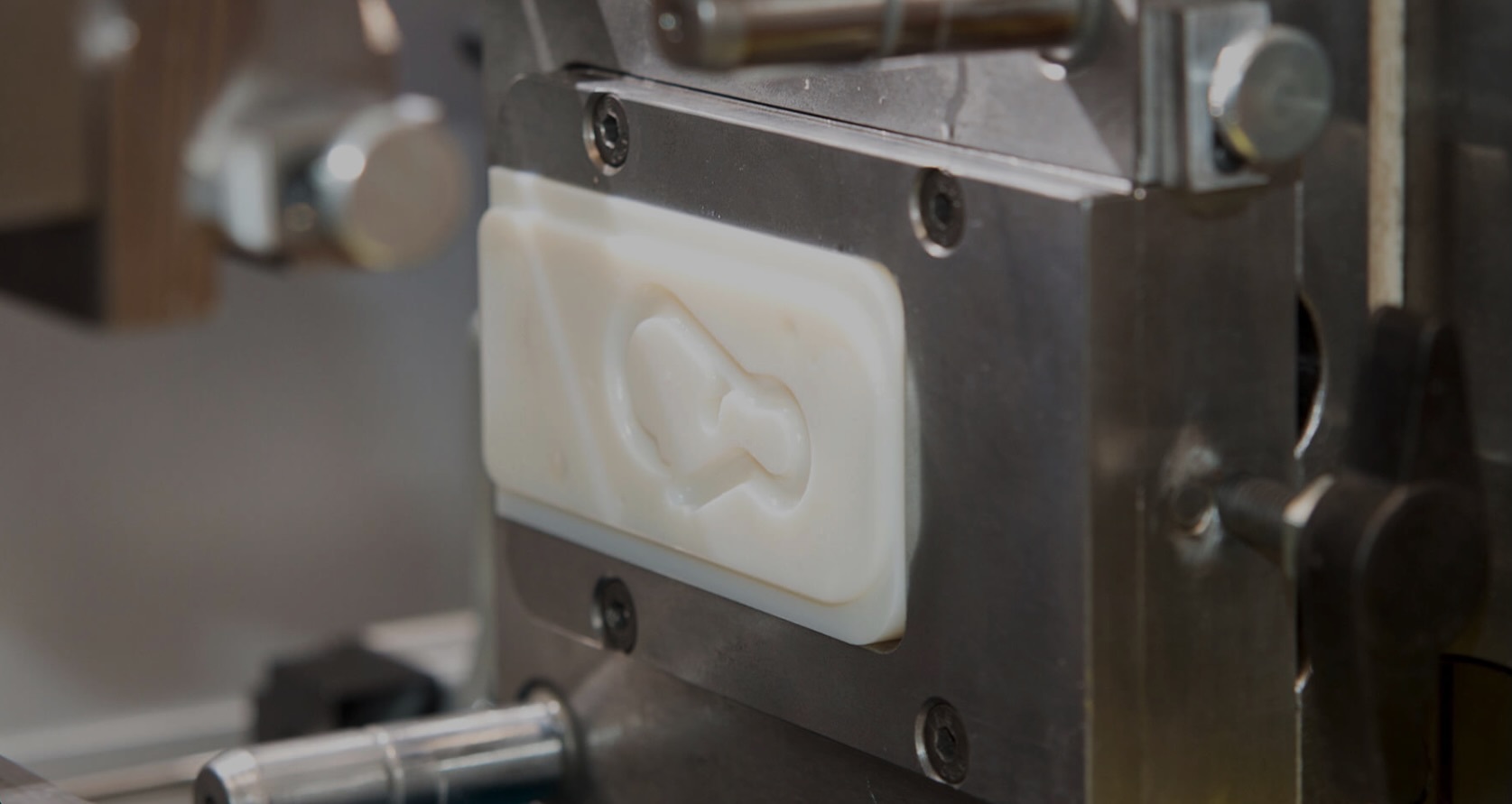

Instead of producing conventional tooling using steel moulds, we use a range of tooling bolsters that can accept printed inserts ready for production.

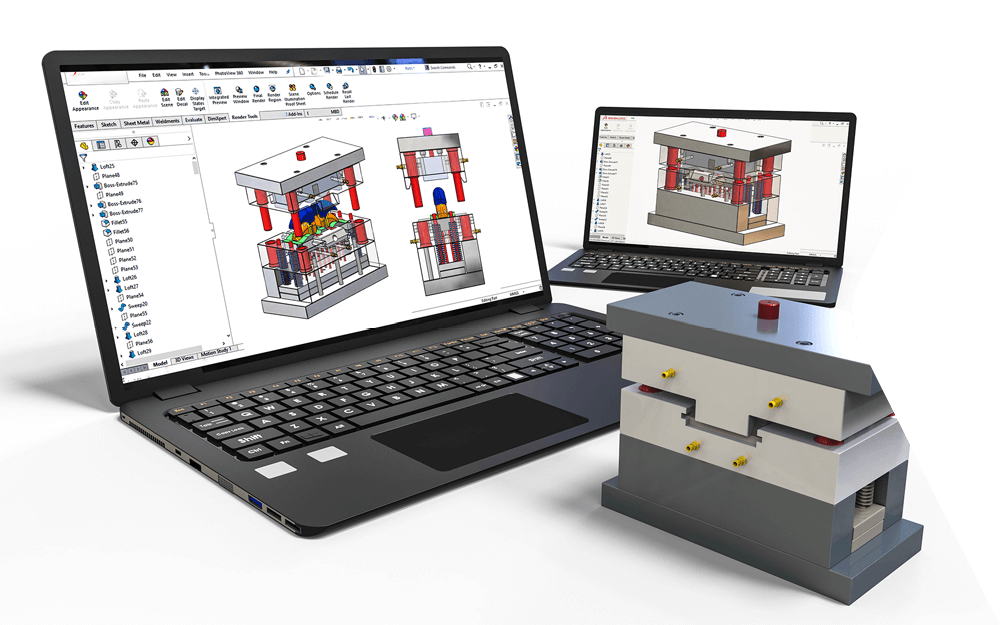

Data covering details of the part required is converted into a CAD file and the mould tool produced and set into a purpose built bolster ready for moulding the part.

Often called rapid tooling this method is used for producing injection moulds quickly and cost-effectively and is particularly suited for low-volume production.

Data covering details of the part required is converted into a CAD file and the mould tool produced and set into a purpose built bolster ready for moulding the part.

Often called rapid tooling this method is used for producing injection moulds quickly and cost-effectively and is particularly suited for low-volume production.

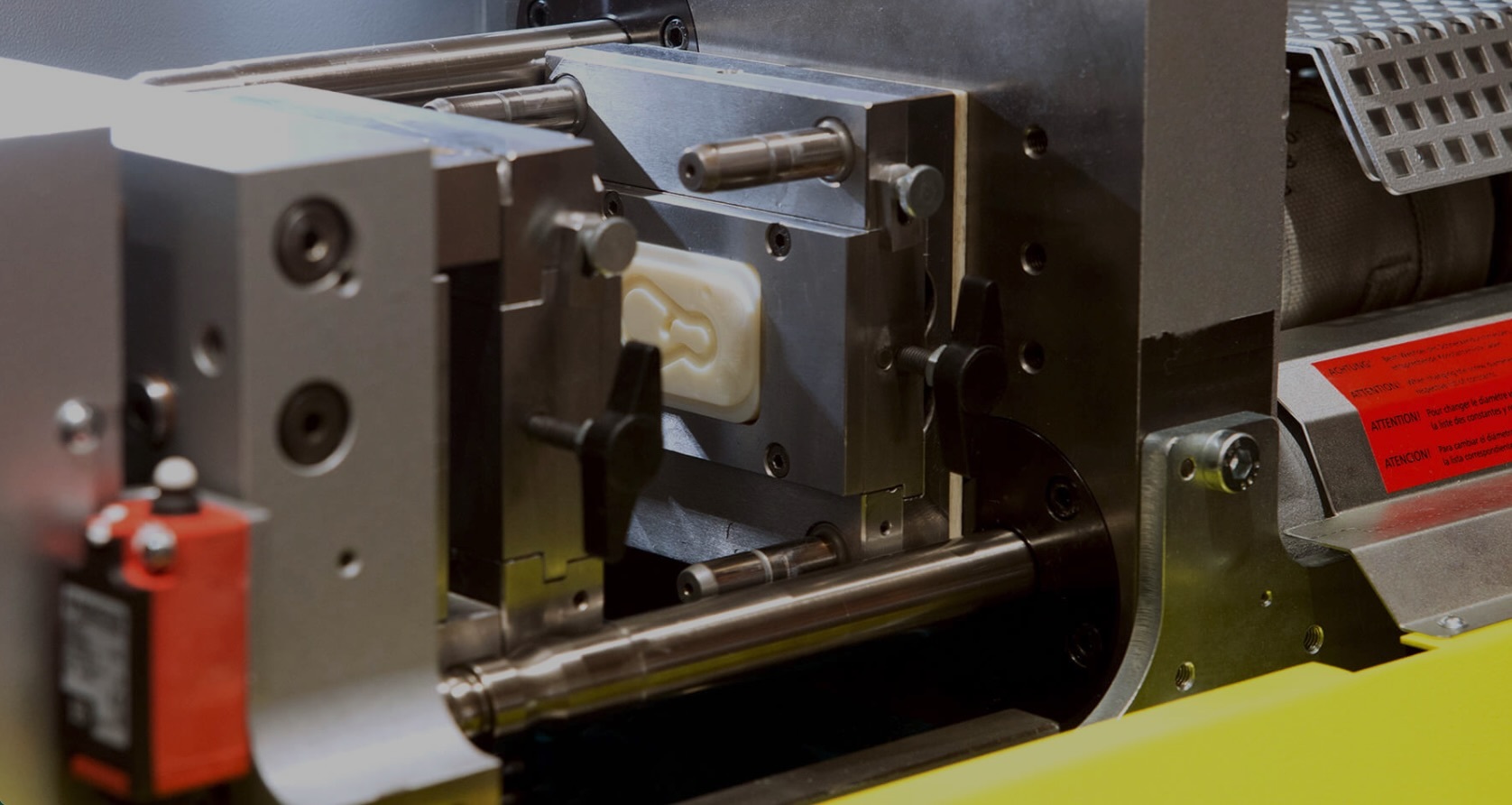

What is a tool bolster?

A tool bolster (sometimes called press bolster or platen adaptor) is the hardened plate or support structure that sits between the injection-moulding machine platen and the mould halves.

Its primary functions are to:

Its primary functions are to:

- Provide a standardised mounting face and hole pattern for different moulds.

- Spread clamping loads across the machine platen.

- Incorporate features for tooling alignment, location, and quick tool changes.

- Provide ports/clearances for utilities (cooling, ejection air, water, hydraulics) and interfaces to the machine (tie-bar clearances, ejector access).

Key Advantages Over Conventional Tooling

1. Faster Lead Times

Traditional steel moulds can take 8–16 weeks to design and manufacture. RIMT, on the other hand, can be produced in as little as hours and days, dramatically reducing the time to market.

2. Lower Initial Costs

Conventional tooling requires high-grade hardened steel and extensive machining, which drives up costs.

3. Design Flexibility and Iteration

Shorter tooling lead times mean design changes can be implemented quickly without major cost penalties. RIMT supports multiple iterations, giving your designers more freedom to refine the products.

Traditional steel moulds can take 8–16 weeks to design and manufacture. RIMT, on the other hand, can be produced in as little as hours and days, dramatically reducing the time to market.

2. Lower Initial Costs

Conventional tooling requires high-grade hardened steel and extensive machining, which drives up costs.

3. Design Flexibility and Iteration

Shorter tooling lead times mean design changes can be implemented quickly without major cost penalties. RIMT supports multiple iterations, giving your designers more freedom to refine the products.

4. Suitable for Low-to-Medium Volume Production

While conventional steel tooling is designed for millions of cycles, many projects only require hundreds or thousands of parts. RIMT is a perfect fit for these shorter runs, delivering professional-quality parts without over-investing in long-life tooling.

5. Support for Bridge Production

When mass-production tooling is still in development, RIMT can fill the gap by producing small batches to meet initial market demand—helping manufacturers launch sooner and generate early revenue.

While conventional steel tooling is designed for millions of cycles, many projects only require hundreds or thousands of parts. RIMT is a perfect fit for these shorter runs, delivering professional-quality parts without over-investing in long-life tooling.

5. Support for Bridge Production

When mass-production tooling is still in development, RIMT can fill the gap by producing small batches to meet initial market demand—helping manufacturers launch sooner and generate early revenue.